In addition to possible introduction of beer production licensing and increase of beer excise taxes, the question about imposing a ban and limiting of PET-containers is catching great interest of the representatives from the industry, related sectors and consumers.

We’ll try to understand why this question has arisen. Is a PET-container so harmful? Maybe this topic is firstly connected with necessity to limit production volumes and alcohol level consumption included in the Anti-alcohol Concept for a period till 2020. (for further information please refer to: http://barley-malt.ru/?p=3388&lang=en)

We paid attention to the question of PET-containers not once(for further information please refer to: http://barley-malt.ru/?s=PET&lang=en).

So, what is a PET-container and does it lose out to a glass bottle?

PET is polyethylene terephthalate, thermoplastic. It is also used for production of plastic bottles that drove out glass bottles from the shops especially in the Eastern Europe. PET package is denoted by 1 in the V-shaped symbol of the closed cycle reprocessing. But it should be noted that plastic polyethylene terephthalate is harmless for human health (according to the estimates of the Federal Institute of the Risk Assessment in Germany) especially in comparison with polyvinyl chloride or polycarbonate.

Raw material for the PET-container is oil and it is limited. Nevertheless producing and processing of this container is very profitable business. Near 100 billions of bottles or 4 million tons in the cubic press-mould, in most cases, already after single use, are directed to China, the most popular country for PET processing. Bottles are processed there, used for sportswear production and sent to Europe again.

“The more you throw out, the more we earn money” sounds business – slogan of PET-containers processors. These processes have a disastrous outcome in the power balance and for environment and cannot be compared with a glass bottle that is produced from raw materials satisfying ecological requirements and as a rule this material is used fifty times. But there is reusable PET – used fifteen times.

In contrast with glass, PET is gastight and carbon dioxide that can diffuse outside and oxygen and toxic agent from the environment air can get inside. All these components make beverage packed in PET containers tasteless and even uneatable compared to similar beverage packed in a glass bottle.

Beverages in plastic bottles must have expiry date up to 40% shorter than in glass bottles.

That’s why re-used PET-bottles are often covered with a gas-proof barrier resin. When using many times this area is attacked, scratched and damaged, so fungi, bacteria or blue-green algae (cyanobacteria) feel good.

PET-bottles can produce different substances into liquid, for example toxic agent – acetaldehyde known as ethanal. This chemical substance appears in the human body as a result of alcohol splitting and is considered to be one of the major causer of the alcohol withdrawal syndrome (especially combined with tobacco smoke).It does harm to liver and is favorable for producing aggressive oxygen free radicals. Acetaldehyde is symptomatic especially for a non-returnable PET-bottle. Reusable PET- containers have a blocker linking acetaldehydes and turning them into uncritical substance.

The Federal Institute for Risk Assessment in Germany believes that a ration of acetaldehyde in PET-bottles doesn’t cause doubt if it doesn’t exceed 6 mg/l.

Nevertheless, numerous tests of products purchased in supermarkets, show that the cheapest beverages in PET-containers contain substances exceeding manifold the required maximum permissible value.

When producing PET-plastics for plastic bottles, stibium is used as a catalyst. Stibium is classified to the potentially harmful heavy metals. A Professor William Schotikiz from the University in Heidelberg proved that water filled in the PET-container is polluted by stibium and with increasing expiration period stibium concentration is also growing. The result figure is 30 times higher than similar water in the glass bottle. Stibium concentration in fresh spring water filled in the PET-container has been increasing by 200 times after 3 months of storing compared to the glass containers.

But the figure doesn’t exceed a maximum permissible value corresponding to norms of the European Product Security Agency. But for Japan this figure is very high and Japan companies uses titanium instead of stibium.

The Federal Institute for Risk Assessment in Germany (BfR) assures that in production of polyethylene terephthalate there are no plasticizers and you shouldn’t draw any conclusions based only on the presence of the word plasticizer (phthalate) in PET term.

It should be noted that new sources, containing information about harmful impact of plasticizers on health produced as a result of solar radiation, emerge.

Do Plasticizers (phthalate) escape or not but certain materials in plastics influence on man health. This fact is very distressing because there were twice as much estrogens in PET- containers as in the glass bottle.

In this case we don’t mean synthetic estrogen – bisphenol A discovered in many other plastic products.

The dangerous thing is that the industry of plastic bottles uses numerous substances and makes a mystery of plastics content so the researchers have troubles to study PET impact on human body.

What is the situation in European countries?

According to statistic data the share of PET-containers is approximately 6,7%. The basic countries using this kind of containers are Rumania, Czech Republic, Bulgaria, Croatia and Hungary – countries with low income. For example, In Rumania with maximal use of PET-containers it is 5.800 Euro per year and in Germany – 29.000 Euro/year.

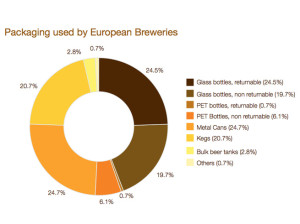

According to the graph the share of the returnable glass in EU is 24,5%, one way glass is 19,7%, can – 24,7% and keg beer – 20,7%.

What package size is much-in-demand in EU?

For example, Germany:

– dark beer – in total 1 billion 766 millions packing units where PET – 2,4 million units, so PET share is equal to 0,135%. Pet-containers size in Germany is 0,5 l.

– light beer – in total 9 billion 539 millions packing units where PET – 325 million units, so PET share is equal to 3,4%. 0,5 liter PET-bottles – 324,8 millions; two-liter PET-containers – only 200.000 packing units.

In Belgium there are only 0,5l. PET-bottles, in France – 0,33l., in Italy – 0,33 and 0,66 l., in Spain – 0,5l., 0,66 and 1l.

It should be noted that in spite of mentioned minimum percentage of PET containers users the most part of beer is bottled to multilayer PET. More detailed information is available upon the request to the Press Office of the Union.

German scientific papers concerning PET-containers are worth to be mentioned. For example, “Flavor and biological stability of beer packed in polymer materials” – this thesis work was introduced by the famous participant of our conferences in Russia Roland Folz, the chair of “technological processes” in Berlin Research and Teaching Institute for Brewing (VLB). The paper is available upon the request (http://barley-malt.ru/?cat=8&lang=en).

The main point of the paper: studying of new PET-materials, for example, multilayer with a scavenger as compared with PET-standard and a glass bottle.

Summarizing conclusions are shocking:

Taking into account the fact that peak oxygen absorption mustn’t exceed 1 ppm during storage; the fall of CO2 content mustn’t be over 15% for the same period and considering the quality characteristics of the product, beer expiration date must be no more than two months if the product is bottled to the standard monolayer PET-container.

The question of using PET-containers for beverages, especially beer is in the focus of the mentioned paper.

Page 6. Permeation of СО2, O2, UV through walls of PET- containers. If used monolayer (standard PET without barrier filter) its barrier-layer effect is not enough for filling beer and other beverages to the mentioned package.

Page 23. So it is impossible to keep the desired storage period (3 months after bottling beer changes color, quality and flavor).

Page 26. Monolayer package passes UV rays and it leads to discoloration.

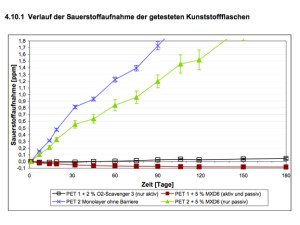

Page 85. The graph illustrates oxygen permeation oxidizing beer compared with PET-standard and PET with barrier-layer effects (there is no similar package in Russia). The difference is obvious.

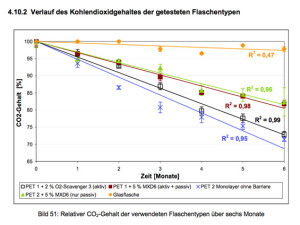

Page 86. The graph shows that PET-standard containers loses 43% of CO2 compared to the glass bottle for 6 storage months, so the bottle simply blows off by half.

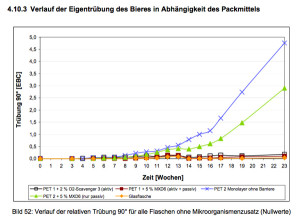

Page 87. The graph illustrates change in beer turbidity compared with the glass bottle – the difference in 500 times for 6 months (EMS for PET – 4,7 and for glass – 0,01) and turbidity is the first factor for generation of microorganisms. Starting on 7th week of beer storage in PET-containers, turbidity appears and starting on 15th week it can be seen by the unaided eye.

All further diagrams indicate the high bacterial potential of beer in PET-containers; after 12th week microorganisms begin propagating – page 87, 88, 89.

An interesting conclusion on the page 108 is also worth to be mentioned: the biggest losses of carbonization and oxygen permeation from outside are typical for the standard PET-bottle.

So, what will become of Russian brewing industry widely using PET containers? By our Union’s estimates the share of PET- containers in the overall package output for beer is 45% that’s why slapdash actions of the Federal Service for Alcohol Market Regulation/the Federal Legislative Assembly are impossible.

During two years our Union managed to hold the question about PET-containers prohibition as it was agreed with the Vice-Prime Minister of the RF Zubkov V.A. and the Federation Council (for further information please refer to http://barley-malt.ru/?p=7655).

Additionally, we asked a question in our website whether to use PET-containers or not? Over a period of two months more than 260 representatives of the industry took vote.

What is your opinion: is it necessary to keep beer in PET containers in Russia?

my voice is for beer in PET (61%, 160 Votes)

my voice is for beer in the glass bottle (34%, 90 Votes)

my voice is for beer in can (3%, 8 Votes)

don’t know (2%, 3 Votes)

total 261

As we see this question is of paramount importance for the industry. We believe that irreversibility of processes towards imposing ban on using of monolayer PET-containers is evident. From the one hand this is due to the poor protective properties of this package and from the other hand – necessity of implementation of the Anti-alcohol Concept.

We can act as Russian Brewers’ Union: advanced the initiative for the self-limitation of the production, refusing of beer and beverage products in plastic package over 2,5l. since January 1, 2014. Unfortunately these steps elicit only a smile.

We consider recommendations of our Union to be closer to the actual state of things. We ask the Government and the Federal Service for Alcohol Market Regulation to study the following proposals:

– introducing comfort transition periods for branch companies (not less than 2 years), linking this item with the required increase in glass bottles output and step-by-step limitation of PET-containers;

– introducing a diversified (reduced) excise tax for beer produced from 100% of malt and filled in the glass bottle, keg and can of 0,5l.

No comments